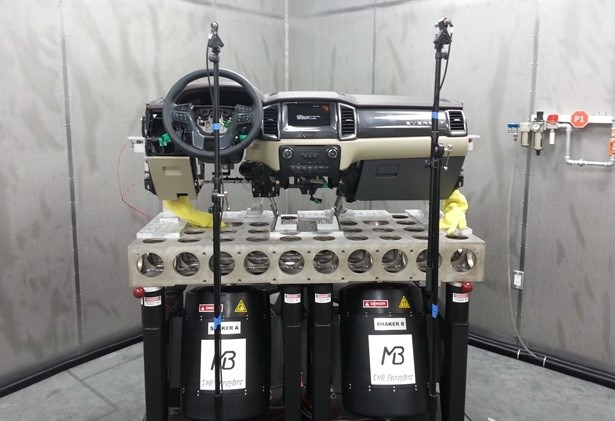

美國MB Dynamics/異音試驗系統Squeak & Rattle Sub-system and Component Testing

Shaker自身噪音低於30dBA,不須外加冷卻系統即可進行異音測試並且符合GM以及Ford規範。

-

At MB Dynamics, we’re proud to provide clients in a wide range of industries with quiet, custom turnkey component testing systems for combined squeak & rattle testing as well as durability testing of different components and subsystems (in 1 to 6 DOF).

Test items can be excited in one or more axes to understand and characterize the physics and root causes of BSRs. Real-world, on-road vibration conditions are multi-axis simultaneous – vertical, fore-aft or longitudinal, lateral, roll, pitch, and yaw – 6 degrees of freedom or 6 DOF. Affordability drives decisions to find BSRs by exciting in one or two – fewer than 6 DOF. That has been a driving force for MB – be effective at finding BSRs with a lesser number of shakers (DOFs) and thus reduce the test equipment cost of finding BSRs. Vertical-only can be effective; sequential vertical then fore-aft then lateral is one step closer to real-world; creating vibration in four or five axes of response simultaneously is even closer; and full 6 DOF systems that are quiet come closest to duplicating in the lab the on-road conditions. MB offers all these possibilities to meet trade-offs of budget, test time, road replication, and BSR detection effectiveness.